GAMMA M 6/7 Axis Portable Coordinate Measuring Machine (PCMM)

Specifications

Details

PMT GAMMA M STANDARD SERIES– High-Precision Portable 3D Measuring Arm

The PMT GAMMA M Series is a cutting-edge portable 3D measuring arm designed to deliver highly accurate, flexible, and real-time inspection and measurement in any industrial environment. Whether used on the shop floor or at a remote site, this portable 3D measuring arm is engineered for stability, ease of use, and unmatched performance.

Constructed with lightweight carbon fiber and designed for rugged conditions, the PMT GAMMA M portable 3D measuring arm meets the needs of industries demanding portable metrology solutions without compromising on precision.

Key Features of the PMT GAMMA Portable 3D Measuring Arm

-

Certified Precision: Every portable 3D measuring armis tested in accordance with ISO 10360-12, ensuring reliable results across diverse conditions.

-

Carbon Fiber Structure: The lightweight frame enhances mobility, making the portable 3D measuring arm ideal for on-site applications.

-

Instant Operation: No warm-up needed – the portable 3D measuring arm is ready to use immediately.

-

Contact & Non-Contact Versatility: Easily switch between probing and scanning without recalibration. The portable 3D measuring arm supports both modes.

-

Environmental Resistance: This portable 3D measuring arm is validated for performance under extreme temperature and vibration via IEC-compliant testing.

-

Modular Axis Configuration: Available in 6-axis and 7-axis setups, each portable 3D measuring arm is tailored to operator ergonomics and application precision.

-

Wireless Option: Enjoy full mobility with a battery-powered portable 3D measuring arm and wireless data transfer.

Portable 3D Measuring Arm Performance

Every PMT GAMMA M unit undergoes strict quality verification, with the portable 3D measuring arm tested under thermal cycling from -20°C to +60°C, and exposed to mechanical shock and vibration—ensuring stability in real-world applications. The portable 3D measuring arm delivers consistent results, even in variable environmental conditions.

Common Applications of Portable 3D Measuring Arm Technology

-

Dimensional verification of parts and assemblies

-

Reverse engineering and CAD comparison

-

In-line and in-process inspection using a portable 3D measuring arm

-

Mold, die, and tooling measurement

- Automotive and aerospace component validation

Technical Specification

ACCURACY - CONTACT MEASUREMENT (PMTArm)

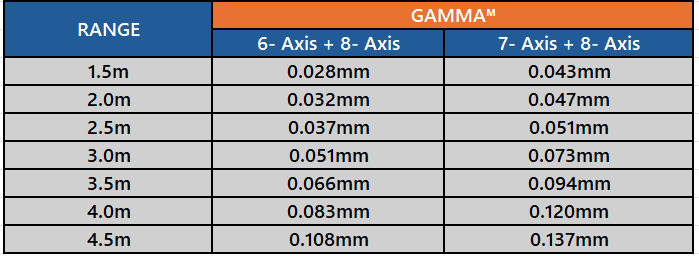

ACCURACY – CONTACT MEASUREMENT (PMTArm+ 8-Axis)

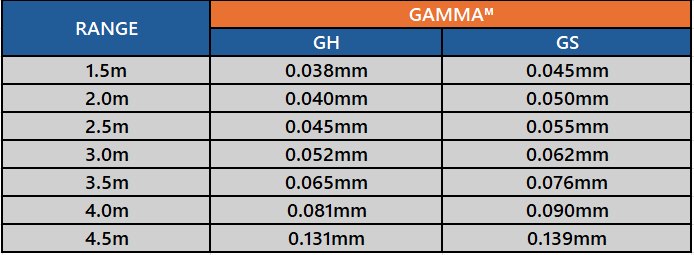

ACCURACY – NON-CONTACT MEASUREMENT (PMTScanArm)

View more about GAMMA M 6/7 Axis Portable Coordinate Measuring Machine (PCMM) on main site